Many people are confused with buying self adhesive labels on rolls so we at Danro Labels thought it would be useful for our customers to have a guide to help them buy their self adhesive labels on rolls. This is to make sure you know the variable specifications we might need to know when you are buying.

Along with the shape and size of the label, the main items we will need to know in detail are the material we use to make the labels, the adhesive, the orientation and the winding.

Materials for Labels on Rolls

The first decision is whether to make the labels using paper-based materials or plastic based material. Paper-based materials use wood pulp as the base composition. Plastic based materials are polymers and are suited to meet certain environmental conditions such as weather or water-proofing.

Paper-based materials can be matt or can have a level of sheen added to them. The sheen is achieved by the addition of china clay and is referred to as semi-gloss or gloss.

Paper and plastic materials can have direct thermal pigments added. Generally, if you require a direct thermal material, you will use either Direct Thermal Eco or Semi-Top coat thermal. It is possible to get plastic based direct thermal but generally, the costs are high and the same results can be achieved more reliably and cheaper using a plain plastic material and resin thermal transfer ribbon.

Plastics used for labelling are predominantly polypropylene (PP) which can be supplied white or clear. Other plastic materials such as PE are also available but cost considerably more than PP. Plastics are very durable and waterproof. They are suitable for outdoors environments and in some cases where the label may be subjected to high mechanical forces e.g. a PAT testing label or tyre label stuck to a tyre being moved around a factory or warehouse.

Thermal printed labels on rolls

If you plan to print on demand with your labels, the labels may be supplied with blank areas that allow you to print specific information on demand. Sandwich labels are an example where a company may have a standard template that it can then print identification onto. This is a large market and Danro is experienced in supplying hundreds of sandwich labelling systems across the UK.

Your choice with respect to thermal printed labels on rolls is normally some form of direct thermal material. If you speak to us first we will give you impartial advice about what solution will work best for you. If the labels have a short shelf-life (say 3-6 months or less), then direct thermal is a suitable method of over printing. For longer duration, we recommend wax or resin ribbons using the thermal transfer method of printing.

Thermal transfer labels last for years as the wax or resin adheres to the label face. Direct thermal material fades over time and can become illegible after 12 months.

Adhesives for Labels on Rolls

There are four main adhesives we offer but specialist adhesives are available – just call us to discuss on 01332 865933.

Removable or Peelable adhesive is suitable for items that do not want to have a permanent label on them. Gifts and gift cards spring to mind as an example.

Permanent adhesive is suitable for around 90% of applications. Permanent adhesive works well at room temperatures and will stick fast to the item. If you attempt to remove a paper based label from an item with permanent adhesive, the paper will tear. It can be possible to remove plastic based materials with permanent adhesives as the plastic face material can be very strong.

Freezer adhesives are suitable for freezing temperatures. It is effectively a stronger version of a permanent adhesive. Freezer adhesives still only work well if the label is applied at room temperature and then frozen; not if applied to a frosted item as the frozen water will form a barrier between the label and the item.

High tack adhesives are suitable for specific conditions such as high mechanical force or wet surfaces. High tack adhesives are designed for specific roles so call us on 01332 865933 to discuss what your application is.

Orientation and Winding of your labels on rolls:

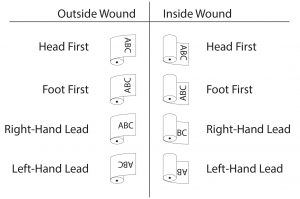

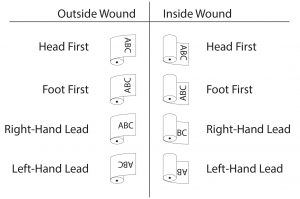

Labels can normally be described as having an inside winding or outside winding. This simply describes whether the label is facing inside the roll or outside the roll.

Labels can normally be described as having an inside winding or outside winding. This simply describes whether the label is facing inside the roll or outside the roll.

Orientation can be more difficult but if you look at the label, generally there will be a left side, right side, top an bottom that is evident from looking at the label. When describing the winding, we will often say head first or foot first to indicate top or bottom of the label. Alternatively, you can describe the label as left hand leading or right hand leading. The diagram shows how the orientations can be described.

So when buying labels, along with the shape and size, just make sure to include the 4 main specifications we need to know:

- Material

- Adhesive

- Orientation

- Winding

Give us a call to discuss on 01332 865933 or click the link or fill in the form:

Labels can normally be described as having an inside winding or outside winding. This simply describes whether the label is facing inside the roll or outside the roll.

Labels can normally be described as having an inside winding or outside winding. This simply describes whether the label is facing inside the roll or outside the roll.

In order to support our customers and help us reduce costs, Danro are now giving free carriage on all orders made over the internet. Commenting on the decisions, John Mayers, MD of Danro said:

In order to support our customers and help us reduce costs, Danro are now giving free carriage on all orders made over the internet. Commenting on the decisions, John Mayers, MD of Danro said: